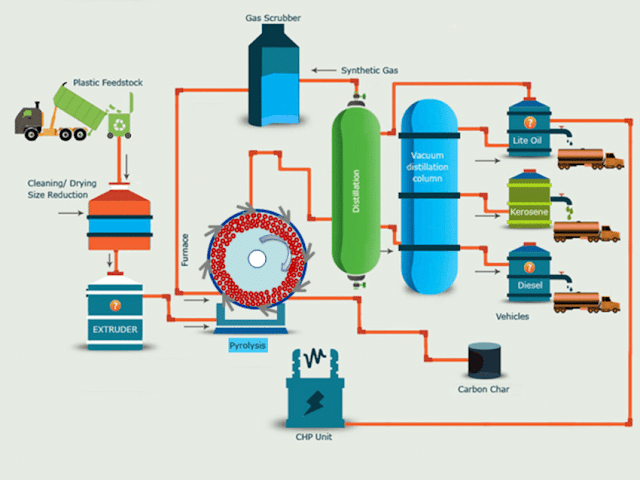

12.B. The segregated plastic wastes our first

shredded to remove the entrapped air and to increase the effective surface area

in the plasma gasification process.

It is essential to maintain anaerobic

conditions the continuous feeding of the shredded polymer waste is utilized

involving the two knife-edged evolves operating alternately in tandem. The

upper valve is opened which allows the feed material to enter and after closing

the top valve, the lower one is opened to allow the feed to reach the heart by

gravity the hearth houses.

Three

graphite electrodes

inclined to each other at an angle of 120 degrees, which acts as the cathode at

the base is the carbon anode which when comes in contact with the catheter

produces the plasma zone.

The electrode

position is controlled by rotating the holding knob from outside the output

gases are mainly carbon monoxide, hydrogen, hydrocarbons and carbon dioxide

that rotted gas after passing through the plasma treatment is made to pass

through the carbon sieves that is tradeoffs reactors.

This process leads to enrichment of

carbon monoxide the catalytic converter is used to convert any traces of higher

hydro carbon to lower forms and finally into carbon monoxide and hydrogen

catalysts like nickel is used for this purpose. The gas is then cleaned in

cyclone separator and scrubber and then cooled in the condenser the carbon

monoxide and hydrogen enriched syngas has high calorific value the gas is

primarily stored in a gas holder and used for generation of electricity with

the help of gas engine.

13. Based on the same plasma based

technology polybag destroyer which can be installed as per the requirement

shredded polymer wastes can also be utilized in the pyrolysis unit. Pyrolysis

is the thermal degradation of wastes in the absence of air that generates a gas

often called syngas a liquid also called bio oil and a solid material called

char consisting of ash and carbon.

The plastic wastes are heated at a

temperature of around 350 degrees to 450 degrees Celsius in the absence of

oxygen and the condensable substances in the form of oil while the non-condensable

particles forms. The gas which can be utilized in burning thus utilizing the

energy for the heating process of the system or else can be utilized for

electricity generation with the help of gas engine. The pyrolysis oil can be

utilized as petrol alternate fuel or PF, which can be utilized in industrial

boilers and generators as it has equivalent calorific value for diesel.

14. The w4u technologies also help in

utilization of construction and demolition waste or simply C&D wastes the

composition of C & D wastes can vary depending upon the types of buildings

being constructed or the age of the building being demolished or renovated. W4U has developed 20 tons per day.

C & D waste crushing systems,

where the C & D waste can be directly dumped into the feeding hopper from

the waste carrying tractor or damper the dumped waste then shall be sent from

the hopper to the crusher through the vibratory chute and inclined belt

conveyor. The debris is then crushed in the jaw crusher the crushed materials

then sent into the rotary trammel using the vibratory chute.

The trammel has mesh size of two

millimeter and five millimeter the different size material has come out from

the trammel the oversize materials come out from the other end the oversize

materials are being used as the aggregates for PCC different works like

construction of pavement car parking and embankment of tar road etc are being

carried out utilizing.

These aggregates the segregated

vines coming out of the trammel are mixed with at appropriate proportion with

binder and water in the mixing machine. The resultant mixture is the feed-stock

for bricks the mixture of optimum quantity is then fed in the die cavity of the

brick-making machine.

The material is then pressed using

the punch the pressure is being generated and controlled in the hydraulic power

pack this gives the mixture a definite shape the bricks are then cured in normal water for

seven to ten days to have the desired strength once found to be in order these

bricks could then be used as construction materials.

15. w4u has

developed technologies to convert agro wastes into briquettes that can be used as effective fuel for cooking

purposes. At the w4u complex highly sustainable

fuel briquettes are created from the dried leaves and dead branches scattered.

All over the Institute and Colony area, they are mixed with the slurry of the biogas

plant cow dung in appropriate proportion, which acts as a binder this is fed in

the briquette-making machine developed by w4u. They

are not only cost effective but very desirable for reasons of simplicity in use

and Eco-friendly aspects the produced briquettes are first air dried.

Before being utilized in smokeless

stove developed by w4u the stove has two

combustion chambers in the primary chamber. The briquettes are burnt and the

same fumes are used in the secondary chamber for heating it has very nominal

smoke emission, which is Eco-friendly and maintains a healthy working

atmosphere for the end-user.

Municipal Solid Waste sorting plant by

Macpresse - Sochi, Russia

https://www.youtube.com/watch?v=h1gbxDzG2Lw

Recycling plastics – Resource efficiency

with an optimized sorting method

https://www.youtube.com/watch?v=I_fUpP-hq3A

পরিত্যক্ত প্লাস্টিক বোতল দিয়ে বিশ্ববাজার জয় উদ্যোক্তা হাবিবুর রহমান জুয়েলের

https://www.youtube.com/watch?v=zE2FW4btKio

যশোরে দেশের প্রথম আবর্জনা প্রক্রিয়াজাত কেন্দ্র |Waste

Processing Center|Shykh Seraj |Channel i |

https://www.youtube.com/watch?v=zxtn3gy3-1U&t=32s

Integrated Municipal Solid

Waste Management Plant

https://www.youtube.com/watch?v=UAscjVNNF0Q

Eddy

Current Non Ferrous Metal Separator - Working Principle [3D Animation]

https://www.youtube.com/watch?v=0PEXpX4u7zA

Rotary

magnetic drum separator

https://www.youtube.com/watch?v=OXouJEwapOY

https://www.youtube.com/watch?v=nlfJt9rXWto

Eco

India_ Could a fuel generated from plastic waste replace fossil fuels and me

https://www.youtube.com/watch?v=c_bNmiDYn5g&t=692s

Mailhem

Ikos - Biogas Plant (Decentralized) with Power

https://www.youtube.com/watch?v=-iYpPzeG7fI

जैविक खाद निर्माण परिसर / Bio

Fertilizer

https://www.youtube.com/watch?v=phGnSOWBsSI